News

News from HAIDLMAIR

Whether new technologies, awards, trade fair events, anniversaries or production records - there's always something going on at HAIDLMAIR.

HAIDLMAIR at the K 2025: Productivity at its best!

The K 2025 in Düsseldorf is the industry event of the year – and HAIDLMAIR will be there to show what "productivity at its best" really means. With innovative technologies, we help our customers reduce costs, accelerate processes and increase profitability in the long term.

Visit the HAIDLMAIR booth (Hall 12 | F35-01) to experience the 6DC design container, which combines state-of-the-art hybrid components, the latest FDU hot runner nozzle and mould surveillance with Mould Monitoring.

The HAIBOX at the Wittmann Battenfeld booth (Hall 15 | B22/A20) impresses with its unique ‘Active Mould’ technology and revolutionary cooling concepts for maximum efficiency.

In the outdoor area (stand CE06), we are sending a clear signal for sustainability with the Wild Pot – 100% PCR material from WILDPLASTIC, perfectly processed with FDU technology.

Visit us at K 2025 and discover how "Productivity for Sustainability" combines innovation, efficiency and responsibility.

New COO

We are pleased to announce that our long-standing CTO Stefan Knödlstorfer is now the new COO of HAIDLMAIR. We wish him all the best and every success in his new role.

HAIDLMAIR at the Fakuma 2024

HAIDLMAIR presents its innovative and sustainable mould solutions at this year's edition of the Fakuma trade show in Friedrichshafen from October 15th to 19th. You will find us in hall B2, booth B2305.

We are looking forward to your visit!

HAIDLMAIR at the Fakuma 2023

HAIDLMAIR presents its innovative and sustainable mould solutions at this year's edition of the Fakuma trade show in Friedrichshafen from October 17th to 21st. You will find us in hall B2, booth B2305.

We are looking forward to your visit!

HAIDLMAIR at the K show

HAIDLMAIR presents its innovative and sustainable mould solutions at the K show in Düsseldorf from October 19th to 26th. You will find us in hall 12, booth D36-01.

Experience our moulds live at:

- HAIDLMAIR (hall 12, booth D36-01)

- ENGEL (Circular Economy Forum Open Air between hall 11 and 16 and hall 15, booth C58)

- Wittmann Battenfeld (hall 15, booth C06)

- Ferromatik/Milacron (hall 14, booth B31)

We are looking forward to your visit!

Founding HAIDLMAIR International Service North

We extended our service network with the founding of our new service center in Langenhagen, Northern Germany We can now serve our customer even better, faster and more efficient with manintenance-, repair- and service works.

Opening Original Spare Parts hall

We are proud to announce that our new HAIDLMAIR Original Spare Parts hall in Schlierbach, close to our main factory in Nussbach, has been officially opened. From now on we have additional capacities in our spare parts manufacturing. Therefore we can provide our customers even better, faster and more efficient with their needed spare parts.

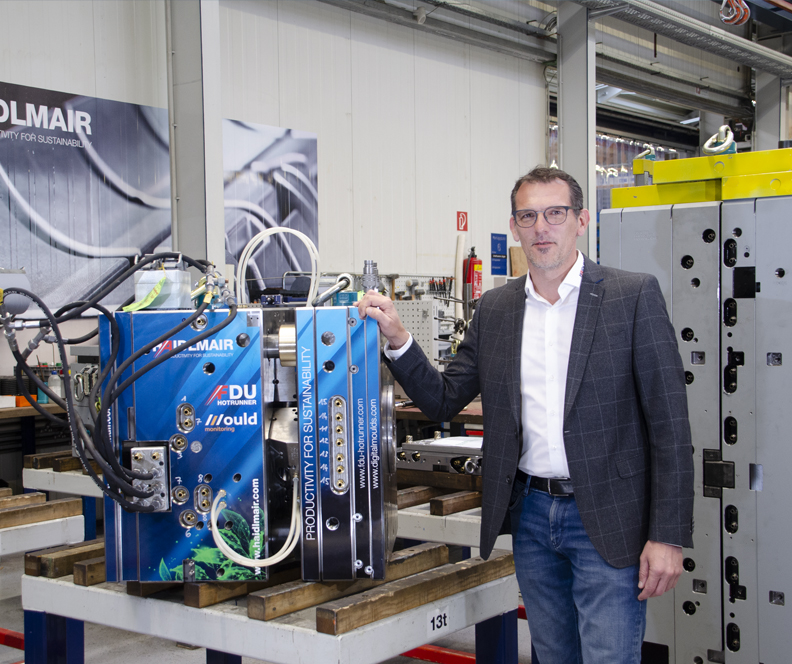

New Productivity Manager

We are very happy to introduce to you our new Productivity Manager Christian Eckhart. The former head of HAIDLMAIR Interantional Service is going to develop and implement further optimisation potentials of our moulds regarding to durability, performance, quality and cost efficiency, always in close coordination with our customers.

More than 25 years of experience in different mouldmaking areas makes him the ideal man for this job. We wish him all the best for his new position.

New head of HAIDLMAIR International Service

Since February 2nd HAIDLMAIR International Service has a new head. Mario Strutzenberger replaces Christian Eckhart in this position. Eckhart switches to the new department "Productivity for Sustainability", which will be working, together with our R&D department, on the further optimisation of our moulds, especially in regards to productivity and sustainability.

HAIDLMAIR is climate-neutral

We are happy that we achieved our goal to be climate-neutral already reached this year. YOu find more information about our sustainability efforts here.

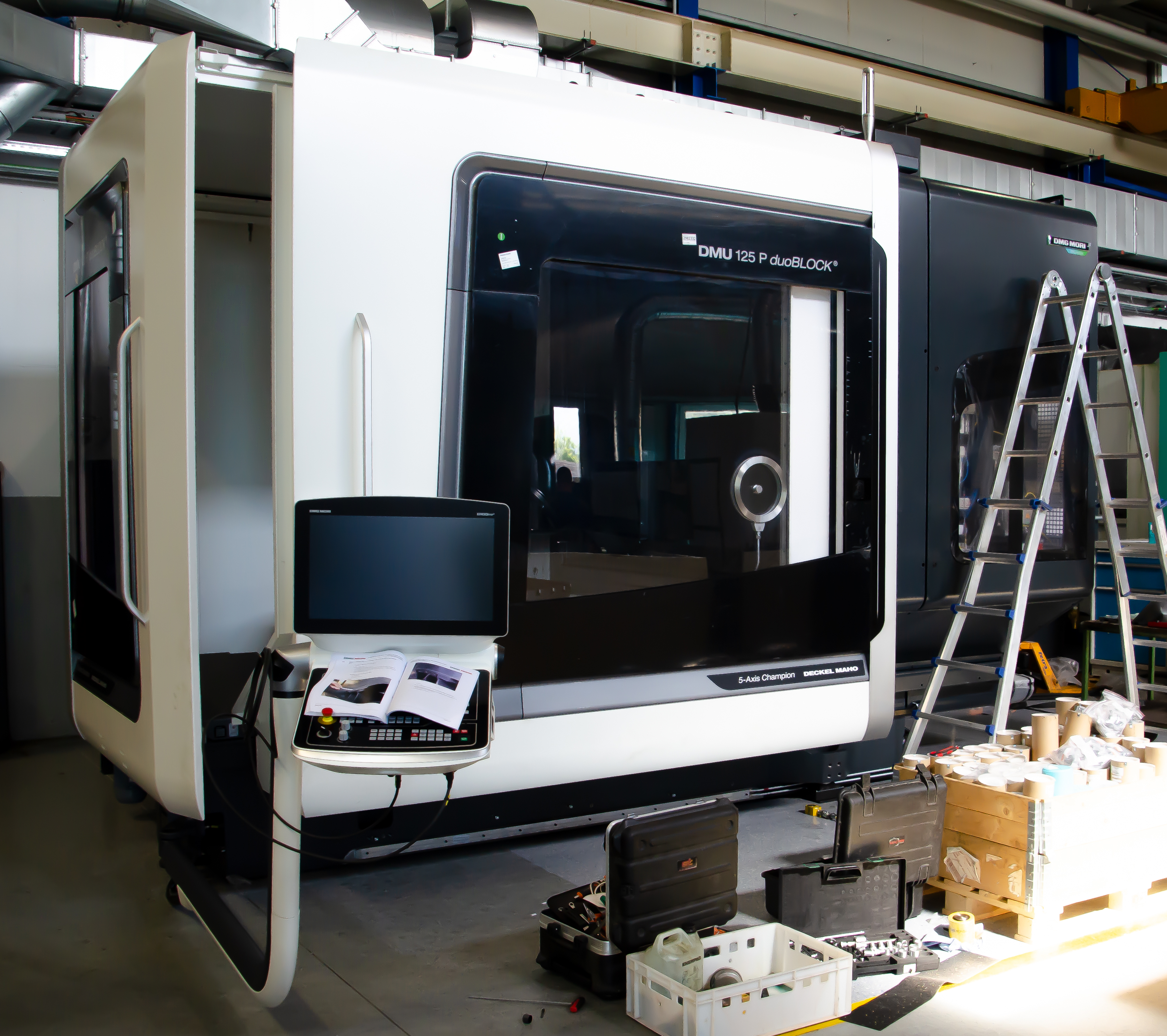

New machine for our prefabrication department

Continous evolution of our employees and machinery is a matter of fact. Our newest innovation is a DMG DMU 125 P duoBlock machine for our prefabrication department. Another milestone to further increase our production quality and efficiency .

Largest order in company's history

We are very proud that our longstanding partners IFCO Systems and Schoeller Allibert continue their trust in us and placed the largest order in our company's history.

More details about the cooperation here.

HAIDLMAIR is member of Global Compact Network Austria

To intensify our efforts in sustainability we joined the Global Compact Network Austria. The United Nations Global Compact is the wordwide largest and most important initiative for responsible management. More information: Global Compact Network Austria

Final Apprenticeship Examinations 2021

Last weeks final apprenticeship examinations for the job as a mouldmaker brought good or excellent results for all our apprentices.

Congratulations to all our successful colleagues!

New machines

We are constantly trying to keep our machinery on the highest level of technology. So it is vital to steadily invest in new machines.

The 3 new machines at HAIDLMAIR:

- A new Fanuc Robocut wire ersoion machine replaces the oldest Fanuc wire edm machine, which were still running in Austria

- A new Hermle C400 for our optimisation department

- A new OPS Ingersoll GE 800 for our countersink erosion department

New Machine Training Center

Our apprenticeship training has a very good reputation, which we built up in the last few years. A part of this reputation is based on the fact that we have a modern machinery in our training center.

Our turning machines there had the potential for optimisation, so we invested in a new turning machine by DMG. The specific model is a DMG CLX 350 V4.

Productivity for Sustainability

Our environment is very impotant for us. Therefor we start the new year with a wide-ranging sustainability strategy, which makes our factory and our products even more sustainable. You can find more information to our Productivity for Sustainability here.

Events

Trade fairs & events

HAIDLMAIR is present at numerous trade fairs and events for the plastics processing industry and mould making worldwide. We are looking forward to your visit.

Contact

ACHIEVE GREAT THINGS TOGETHER

As global market leader for injection moulds, together with our customers we work to create a better and more sustainable future. Do you want to realise your ideas and concepts with us?

We are looking forward to your message.

We will process your request as soon as possible and get in contact with you!